1. Why use an induction heating machine for mold heating?

At present, the mold is heated by an ordinary electric heating oil bath oven, whose main principle is to heat the mold through the heat radiation of the oven wall and the heat exchange between hot air and the mold. The common electric heating oil bath oven has the disadvantages of the long heating cycle, low heating efficiency, high requirement for operators’ experience, and high energy consumption. As a heating technology, induction mold heating machine has the characteristics of precise heating depth and heating area, high heating power, fast heating speed, high efficiency, small energy consumption, easy to control the heating temperature, easy to realize the automation of the heating process, etc. Since the 1930s, induction heating technology has been widely used in industrial production, so far it has shown more and more extensive application prospects in many industrial fields.

At the same time, the investment cost of induction mold heating machine is low, especially the temperature control is accurate, and it will be applied to the preheating of plastic molds in various industries such as mobile phones and computers, which will greatly improve the quality and production efficiency of products.

2. What is an induction mold heating machine?

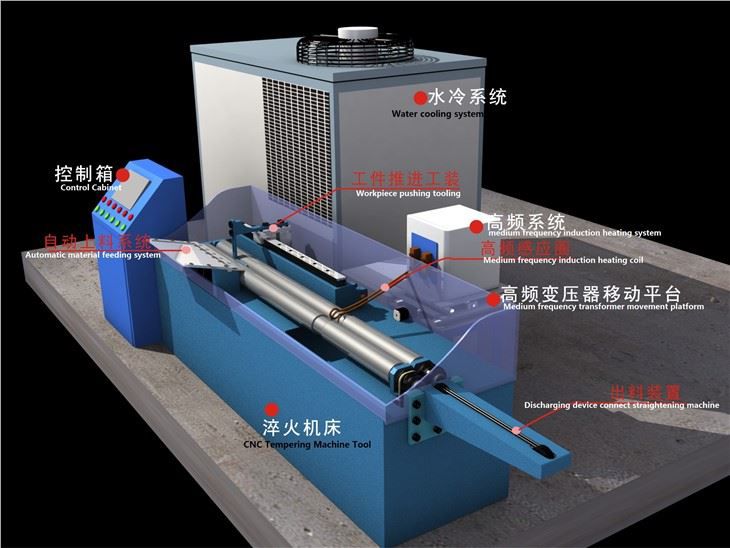

Induction mold heating machine: Continuous induction heating, preheating one mold approximately every 30 seconds, induction mold pre-heating machine is heated by integrated multi-point measuring mold induction preheating equipment for temperature closed-loop control, and the mold is preheated to the served temperature.

The difference between the mold outer wall and inner wall temperature is small so that the overshoot tendency of the internal temperature of the mold is reduced. With our induction mold heating machine, the heating process temperature is stable and easy to control, greatly improving production efficiency and product quality.

3. What are the induction mold heating machine advantages?

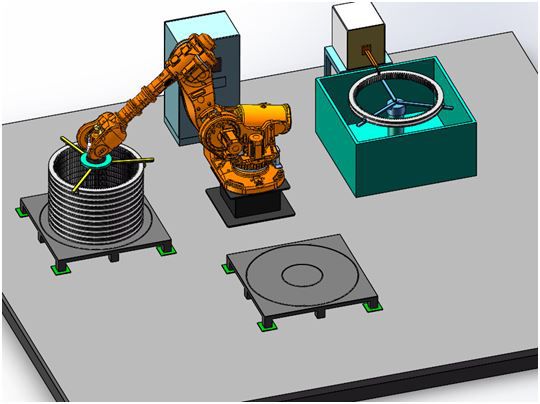

◇ Our induction mold heating machine adopts induction heating preheating mode: high efficiency, fast preheating speed, multi-stage control of preheating area temperature, uniform preheating temperature, no oxidation phenomenon.

◇ Adopt the second generation of DSP intelligent induction mold heating machine, using power and temperature double closed-loop control, to realize the temperature curve control function at the same time, 4-point thermocouple temperature display, 1-channel infrared temperature display protection function. In the heating process the mold overall temperature does not exceed the set temperature ±5℃; At the end of heating, the temperature difference of each part of the mold is less than 8℃; The heating power is adjustable, and can be adjusted according to the measured mold temperature, and can realize the insulation function.

◇ On-line thermocouple closed-loop control system, high-temperature control accuracy, fast control speed, real-time temperature display, and record.

◇ Real-time temperature alarm function, timely send out the alarm signal when the production line beat is abnormal, including high and low-temperature alarm, heating timeout alarm, etc.

◇ Professional online tooling positioning fixture, to ensure that each mold is heated when the positioning is accurate, to ensure the temperature uniformity, and preheating speed.

◇ With constant power, constant current, constant temperature arbitrary switching combination function, convenient for different load heating applications.

◇ With remote control and internal control operation mode switching, convenient control mode switching.

◇ With load matching indicator function, convenient and intuitive guidance of load matching selection.

◇ The induction mold heating machine has the function of recording the induction mold heater alarm status, which is convenient for inquiring about the historical data of the mold heater.

◇ The induction mold heater has the function of grading login between administrators and operators to avoid the adjustment of the heating process by unauthorized personnel.

◇ Intelligent DSP induction mold heating machine operating state and parameters such as voltage, current, power, frequency, etc. adopt real-time acquisition, monitoring. At the same time, these states can be directly connected to the centralized control network through the communication interface inside the power supply, and the required parameters can be transmitted to other controllers, such as an industrial computer, numerical control system, notebook computer, remote control center, etc., to meet the requirements of the workshop Internet of Things.

◇ With Chinese, English, and other language operation interface.