WHAT IS INDUCTION heat treatiing?

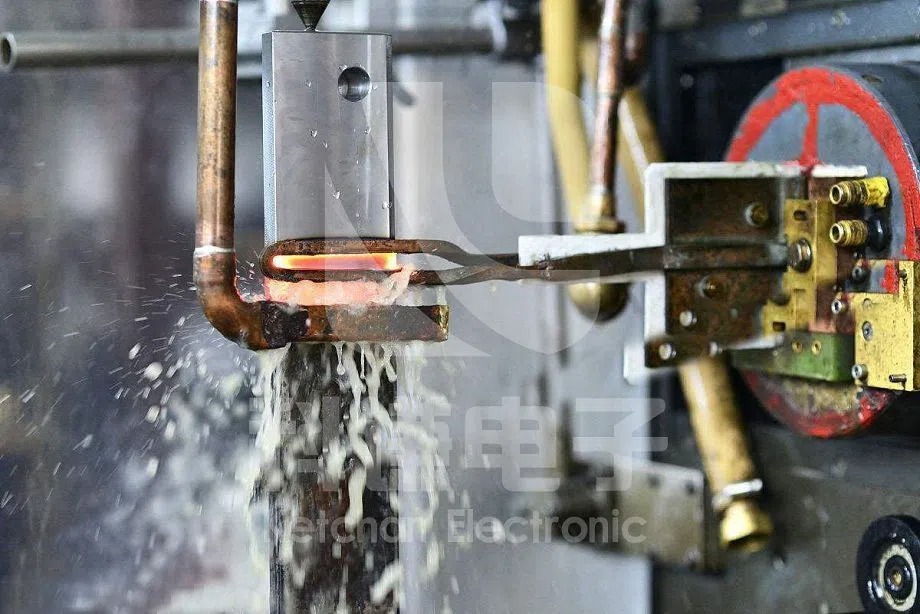

Induction heat treating is a surface heat treatment process in which the workpiece is partially or completely heated by the principle of electromagnetic induction. This induction heat treatment process is often used for surface quenching, but also for partial or total preheating, annealing, tempering, hardening & tempering, and so on. An induction heater is characterized by light decarburization, fast heating speed, partial or total heating, small workpiece deformation, high efficiency, and easy automation. Widely used in automobile, machinery, ship, oil, mining, and other industries.

● All kinds of hardware tools, hand tools hardening.Such as pliers, wrench, hammer, ax, screwdriver, scissors (garden scissors), etc.

● All kinds of auto and motorcycle accessories hardening. Such as crankshaft, connecting rod, piston pin, sprocket, aluminum wheel, engine valve, rocker shaft, driveshaft, small shaft, fork, and so on quenching;

● All kinds of power tools. Such as gear, axis;

● Machine tool industry, Such as machine tool bed surface hardening, machine guide hardening, etc.

● All kinds of hardware metal parts, machining parts. Such as shaft, gear (sprocket), CAM, chuck, clamp, and so on quenching;

● Hardware mold industry. Such as small mold, mold accessories, mold hole quenching.

1. Steel Plate Induction scanning hardening system

2. Road wheel raceway induction hardening

3. Slewing bearing inner tooth induction quenching

4. Double station induction heat treatment system

5. Wire Bar Online Heat Treatment For Heating Coil Spring

6. Axis Pin Heat Treatment With IGBT Induction Heating Machine