WHAT IS Induction Annealing

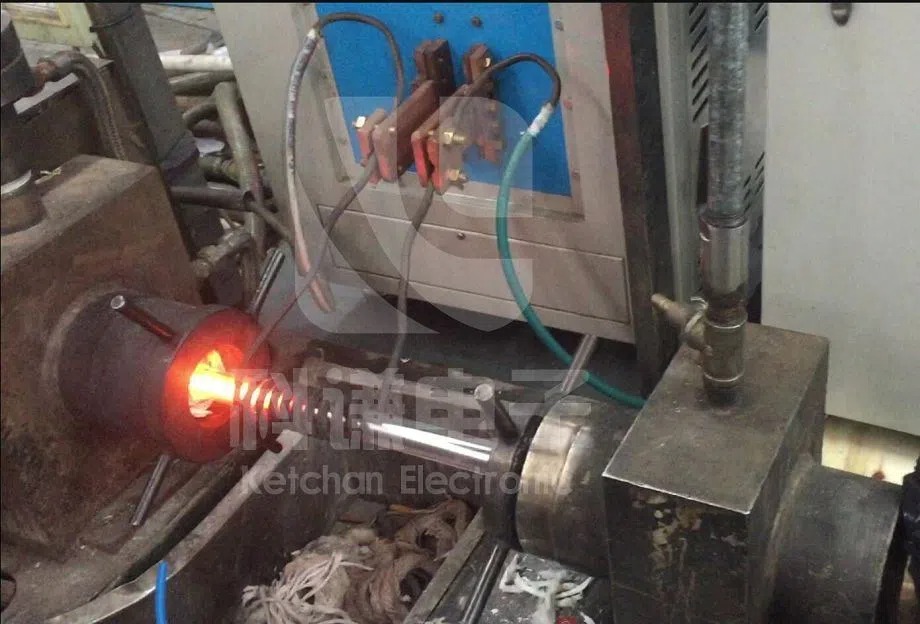

Induction Annealing is the workpiece of heating to the proper temperature, according to the material and workpiece size in different heat preservation time, and then slowly cooling, cooling speed is the slowest), to eliminate the residual stress inside the purpose is to make the metal internal organization at or near equilibrium state and obtain good process performance and use of performance, or for further quenching organization.

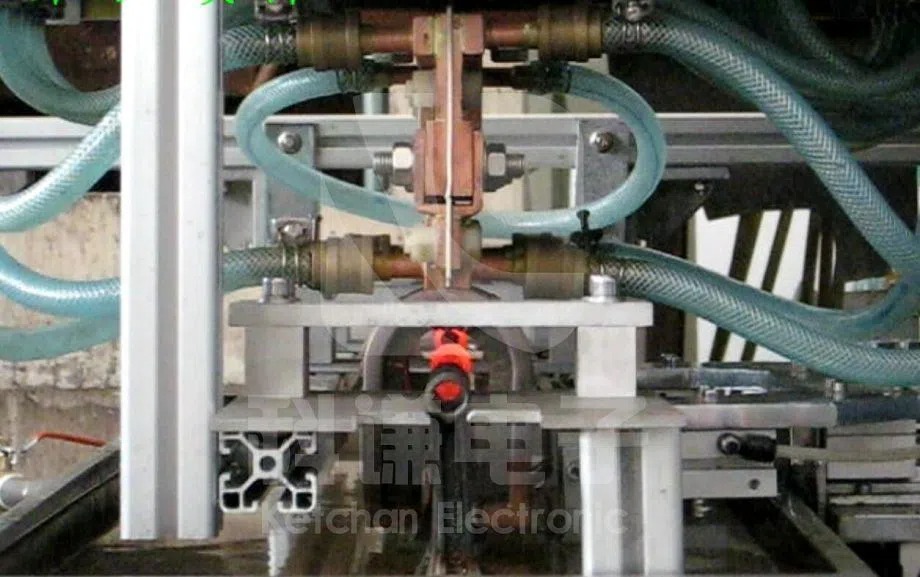

The bullied action features of the induction heating machine can be carried out directly by the bulls-eye function of the induction lighter, which will reduce heat loss and energy loss to the greatest extent, increase production efficiency and improve product quality. At the same time, the heat can be precisely controlled, which can reduce the temperature of welding and thus the cooling rate. It also reduces the risk of cold cracking and hardening.

It is widely used in the heat treatment industry to anneal and temper pipes, blades, steel strips, wires, copper wires, steel plate, copper strip, aluminum plate, and cables, etc.

1. Steel Wire Online Induction Annealing System

2. Stainless Steel Tube Online Induction Solution Treatment

3. Saw Tooth Alloy Induction Annealing

4. Automatic Needle Roller Bearing Induction Annealing System

5. Full Automatic Shell Casing Induction Annealing System

6. Automatic Motorcycle connection Rod Induction Annealing Line