Outer race, inner race, Hub Bearing Induction Hardening Tempering

1. What is the hub-bearing Induction Hardening?

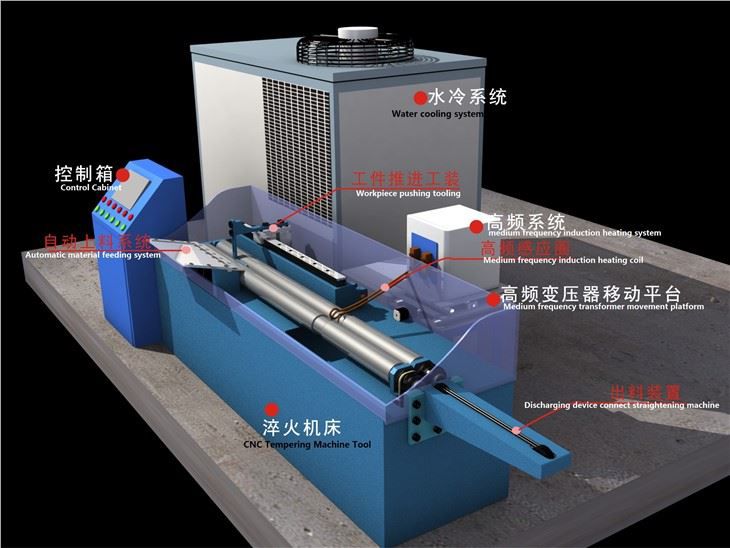

The outer race, inner race, wheel hub bearings induction hardening tempering equipment is suitable for many kinds and specifications constant velocity universal joint outer race, inner race parts, and automobile wheel hub bearings induction hardening projects.

CNC induction hardening machine tool adopts an intelligent CNC system for centralized control, material feeding, material discharging, and the working process workpiece movement/turnover process are all completed by the manipulator, the station rotation is automatically completed by the rotary table.

This induction heat treating system provides induction hardening stations and one induction tempering station to complete the different automotive parts hardening and tempering processes on the different stations at the same time.

Induction heating power supply adopts the international leading transistor solid-state induction heating power supply, full digital control technology, with perfect protection function and digital parameter setting and display interface.

The special induction heat-treating process parameter management monitoring system can record the monitoring equipment data in real-time and has the historical data query function.

The induction hardening system can be equipped with an online laser printing function and an online non-destructive testing system.

Outer race, inner race, hub bearings induction hardening tempering system with a high overall intelligent degree and high working processing efficiency.

2. How to design the hub bearing induction hardening coil?

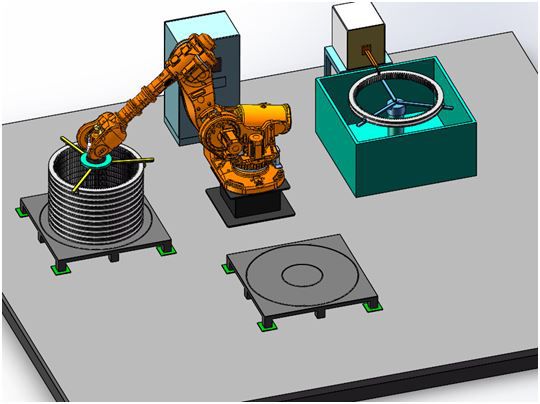

The below picture is the model designed for the inner hole hardening inductor and the outer circle quenching inductor. The gap of conductive copper pipe is 2mm, insulation board must be installed. And 2mm thick PTFE insulation board is used here.

The magnetic body can be cemented with 504 adhesives, and the final forming of the inductor conductive tube needs to be wound and fixed with fiberglass cloth.

3. Outer race, inner race hub bearing induction hardening tempering process parameter

l Induction Hardening Machine Power 250KW 8-30KHZ

l Parts max. Height:200mm

l Induction coil moving distance:200mm

l Max moving speed:200mm/s

l Parts rotation: 20-150rpm can be adjustable

l Max turning diameter: 200mm

l Hardening diameter:150mm

l Repeated positioning accuracy:0.1mm

l Repeat rotation pendulum difference:0.1mm

l Induction hardening tempering system features Automatic loading and unloading, four stations. Can be connected with other machining production line, high production efficiency.