Starter Rings, Gear, Rings Raceway, Slewing Bearing Induction Hardening

What is slewing bearing induction hardening?

Large slewing bearings are used in wind turbines and other energy industry equipment where conditions are harsh. In order to bear a large dynamic load, the slewing bearing roller table can be hardened by induction heating. Uniform heat treatment without a soft belt is realized by adopting a soft belt-free technology. Compared with the traditional furnace carburizing, the induction hardening speed without a soft belt is faster and the energy consumption is lower, and a process has been developed to achieve the same effect on the medium carbon steel slewing bearings. The presence of preheating coils, with independent induction heating power sources, allows the heating rate to be adjusted in order to adjust the heating process according to the steel properties. The preheating function ensures that the depth of the hardening layer is more than 10mm without reducing the scanning speed or productivity.

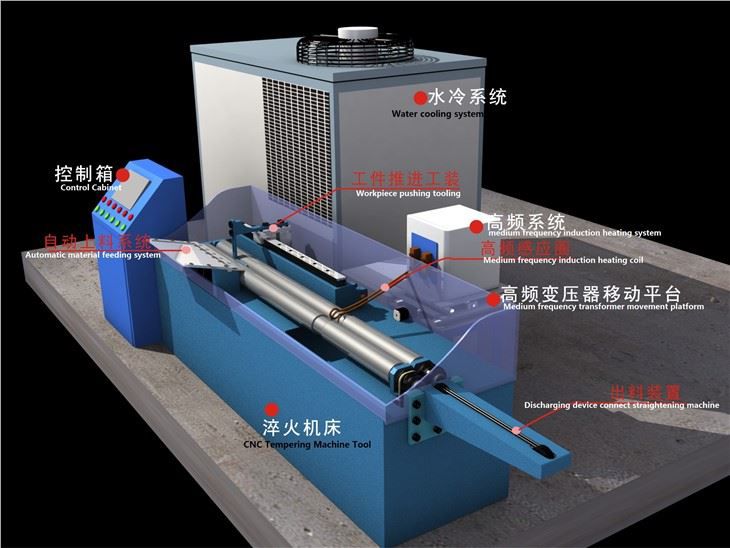

How to do the slewing bearing induction hardening process?

There are some difficulties in induction hardening large bearing rings, so it is necessary to develop process parameters, induction coil, and spray devices for the shape and size of each specific bearing roller table. The geometry of roller beds usually requires different quenching cooling strengths. The inductor is equipped with a magnetic conductor to gather magnetic field lines where high power is needed to improve the induction heating power on the workpiece. The use of two inductors on each heating element allows for a faster scanning speed while maintaining the required hardened layer. When the scanning speed is 1mm/s, the depth of the hardening layer above 10mm can be reached. The scanning hardening speed ensures that the heated workpiece surface temperature will not cool until it is sprayed and cooled. The heating frequency of 1 ~ 5kHz is most suitable for the requirements of a deep quench layer. The power output of each preheating inductor during stable scanning has been set to heat the surface temperature to 920 ~ 970℃. For the heating inductor, the power output is set to maintain the surface temperature and heat to the desired depth through heat conduction. The main spray and auxiliary spray devices are installed on the heating components to ensure that the quenching cooling medium covers the entire length of the roll table of the workpiece during the quenching process. Correct selection of quenching cooling medium polymer concentration and temperature to avoid the workpiece in the quenching process crack.

What are the applications of the complete slewing bearing induction hardening system?

l Induction heating is normally used for hardening slewing bearings, industrial gears, rings, bearings, raceways, ball track, etc.

l Workpiece diameter range: diameter 800-6000mm.

l Match 200KW induction heating machine.

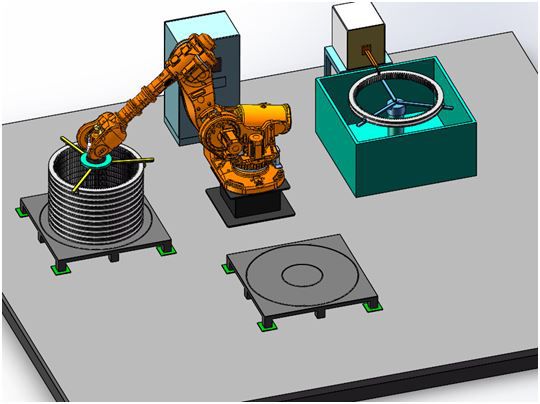

Zhengzhou Ketchan Gear, Slewing Bearing Induction hardening equipment configurations

The most advanced induction hardening system for Slewing Bearing, Starter Rings, and Gear Rings Raceway hardening. The complete induction heat treating system includes:

l Slewing bearings, ball track CNC induction hardening machine tool

l IGBT induction heating machine

l Induction hardening transformer

l Raceway hardening inductor

l Gear hardening inductor

l Energy monitoring system

l Water cooling systems

Please contact us for a detailed technical proposal along with quotations regarding the complete slewing bearings, gears induction hardening machine.