1. How to do Anti Collision Beam Pipe Induction Heat Treatment?

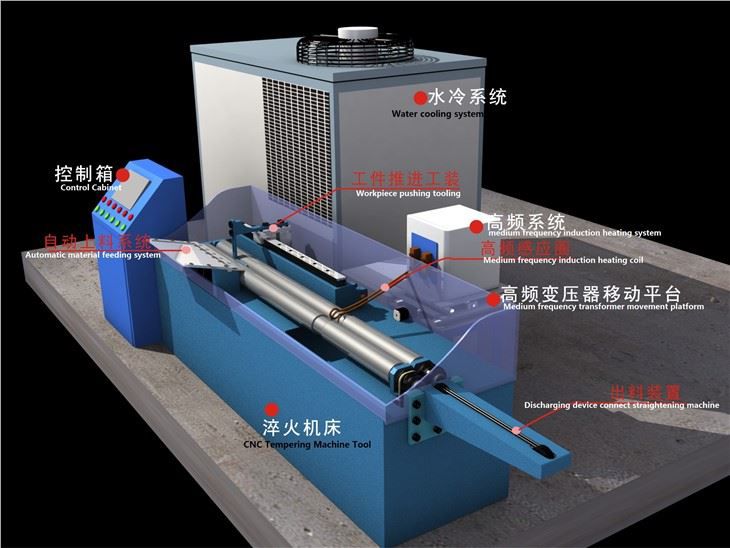

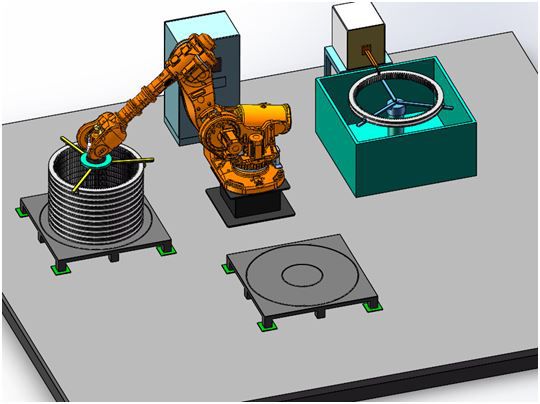

This anti-collision beam pipe induction heat treatment system has dual-channel operation, which can be controlled centrally or independently by separate channel control. The operation and conversion are convenient.”Tube & Pipe products” after artificial concentration into the feeding, feeding the workpiece into induction heat treatment system production line conveyor belt, the steady transmission, automatic production line complete workpiece rotation, heating – cooling (quenching), transportation, heating( tempering), cooling, discharging, etc, in the process no need a manual operation (after the induction heat treatment system finish final testing), belong to full automatic induction heat treatment system for pipe & tubes quenching and tempering.

The quenching coolant is automatically filtered and circulated, and has the function of alarm or stop under overrunning conditions (such as overload, overtemperature, workpiece loss speed, fault).

The complete anti collision beam pipe induction heat treatment system layout is about 20m*5m.

2. Anti Collision Beam Pipe Induction Heat Treatment System Technical Process

◇ Anti collision beam pipe induction heat treatment system production speed is 6m/min.

◇ The anti collision beam pipe induction heat treatment system mechanical rotation and transmission parts should be flexible and reliable and the noise and heat generated by the parts in the movement should meet the product accuracy and the requirements of the national machinery and equipment industry standards. The equipment and components meet the service life stipulated by the industry;

◇ The components of strong and weak electrical appliances should be safe and durable, and fully meet the relevant national technical standards;

◇ One-button quick start working mode of the anti collision beam pipe induction heat treatment system, the “man-machine dialogue” of the display panel, and related instruments (interface) must be in English and other request languages.

◇ Equipped with the function of “double working positions” — gymnastics operation or separate operation of the anti collision beam pipe induction heat treatment system production line, as well as the separate operation function of each module heat treating equipment;

◇ The anti collision beam pipe induction heat treatment system production line is equipped with the alarm or stop function under the overrunning conditions (such as overload, overtemperature, workpiece loss speed, fault) of each module;

◇ Productivity with “intermittent quenching” function, control error is not more than 5mm;

◇ Maintenance sockets and lights should be set in the production line. The external power cable is required to run reasonably and neatly, and the cable (or copper bar) entrance is located in the power supply bottom or top.

◇ The appearance of the anti collision beam pipe induction heat treatment system production line should be beautiful, adopt the “box type” structure, and can meet the requirements of heat dissipation and convenient maintenance, equipment color according to the buyer’s manufacturer.

◇ After running the whole anti collision beam pipe induction heat treatment system production line, there is no leakage (electricity, gas, quenching liquid, coolant, oil) and other phenomena. The liquid and airflow direction signs are prominently displayed in each pipeline. The inlet and outlet water pipes adopt a quick changeover head for easy connection. Pressure gauges and temperature gauges should be installed on the secondary cooling water pipes to monitor water pressure and water temperature.

◇ The main circuit of the water cooling part of the power supply is made of copper pipe to reduce the generation of scale. The water pipe fittings are all made of 3/8 copper triplet quick joints for easy maintenance.

◇ The design, manufacture, and installation of the production line shall comply with the national and industrial standards and must meet the requirements of safe production. Safety protection devices shall be added for the parts with potential safety hazards, and conspicuous notices shall be given.

3. How to choose the suitable Anti Collision Beam Pipe Induction Heat Treatment?

◇ Let us have your Anti Collision Beam Pipe drawing?

◇ Induction heat treatment requests?

◇ Once made clear about your requests, our technical team will make a suitable anti collision beam pipe induction heat treatment system technical proposal for you.