1. What is the crane wheel Induction hardening system?

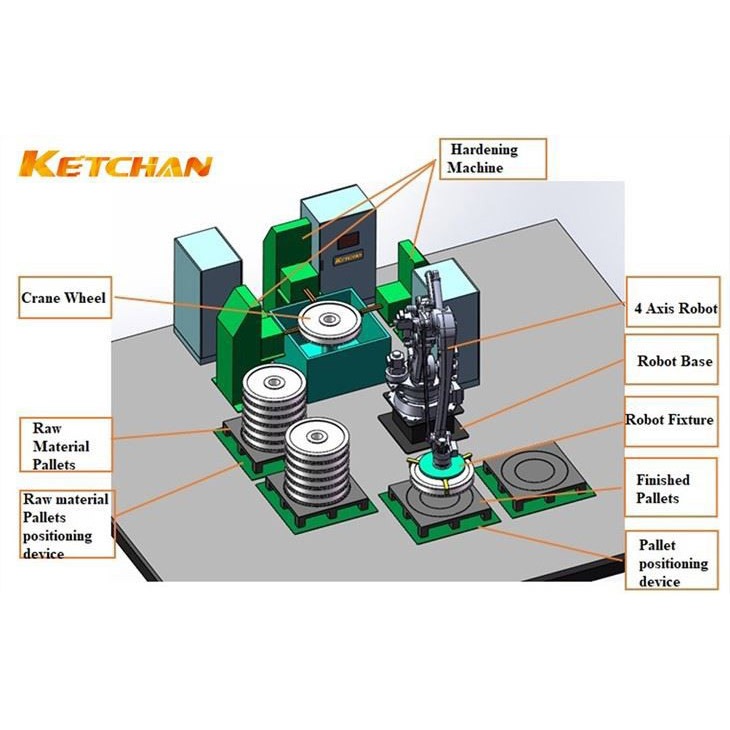

The crane wheel Induction hardening system consists of an induction heating power supply, water cooling and hardening system, multi-station hardening machine tool, manipulator loading, and unloading, operating system, and so on.

Mechanical loading and unloading grippers

2. How to do the crane wheel induction hardening process?

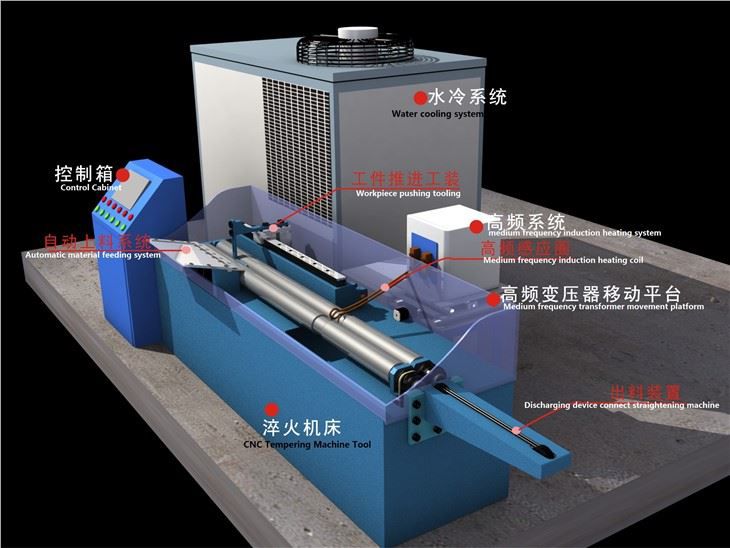

No.1 Crane wheel induction hardening system(wheel overall hardening process)

The crane wheels are placed at the material loading station, the mechanical arm grabs the wheels and clamps them on the machine table, the induction coil through the automatic control, synchronously move to the corresponding wheel heating position. When the induction coil is in place, the heating power is turned on, when the product is heated to the hardening temperature, the heating power supply stops synchronously, the induction coil quickly moves back to standby, The wheels are put into the quenching liquid tank for immersion quenching treatment (the quenching liquid in the tank is designed to rapidly stir and circulate to ensure consistent cooling temperature), ensuring quenching process quality.

The following is the crane wheel induction hardening system overall quenching process, which mainly avoids the soft belt at the wheel beginning and end of quenching. According to the wheel size, the heating equipment should have enough power. The below picture is the operation site.

No.2 Crane wheel induction hardening system(wheel scan hardening process)

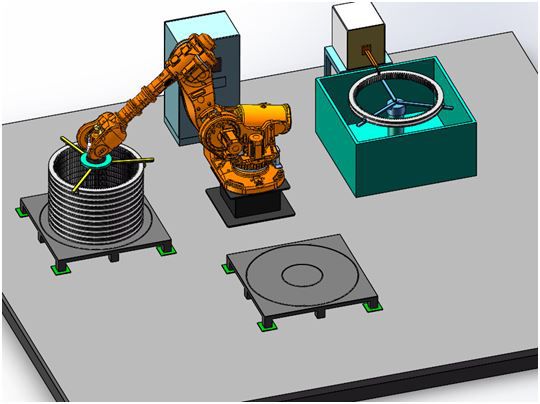

Mechanical arm or (manual hoisting) to clamp the wheels on the machine table, the induction coil through automatically control, synchronously move to the corresponding wheel heating position, when the induction coil is in place, the heating power is turned on, spraying liquid cooling delay start, when the wheel rotates a circle, the heating stops, spraying liquid cooling time delay stops, the induction coil move back mechanical arm or (manual hoisting) transfer the wheel to the quenching station.

The following is the crane wheel induction hardening system local scanning quenching process, and there will inevitably be a soft belt at the junction of the beginning and end of quenching, because of the local heating, so the equipment has enough power is ok. The picture below is the operation site.

3. Crane wheel induction hardening system technical data

Model | KQL-1000LS |

Machine action mode | The coil moves back and forth servo, left and right adjustment/the product moves up and down servo |

Quenching way | Immersion \Section quenching |

Working method | Manual and automatic |

Loading and unloading mode(optional) | Special manipulator |

Number of quenching stations | 1 station |

Workpiece clamping method | Pneumatic chuck with three-jaw |

Suitable for the maximum rotary diameter of the workpiece | Φ1000mm |

Maximum total workpiece weight | 500kg |

Repeat positioning accuracy before and after coil | ±0.05mm |

coil lift and repeat positioning accuracy | ±0.05mm |

Coil moving speed | 0~2000mm/minute |

Rotation speed | 20-150r.p.m |

Transformer adjusting and moving frame | 2 sets |

Transformer adjustment mode | electric |

In total, we have done many different crane wheel induction hardening systems before, and we have the matured heat-treating process for your letter. So if there is any technical confusion or technical support from you, welcome your letter at any time to Zhengzhou Ketchan Electronic Co.,Ltd.