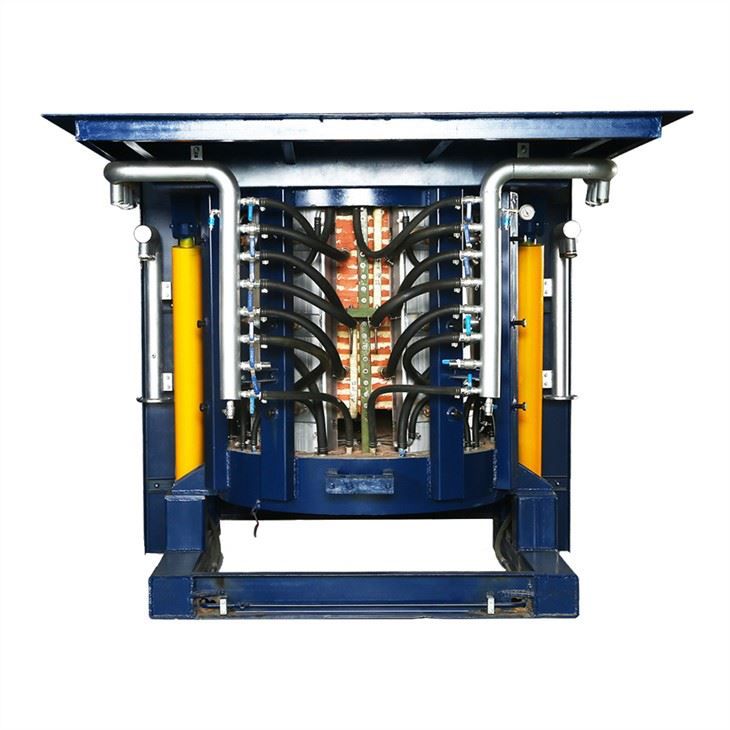

Introduction of Metal Smelting Furnace

This metal smelting furnace of the power supply for the inverter series circuit, through the reactor for capacitor charging, to make sure the output voltage of the inverter is stable, at the same time because of the existence of capacitance can prevent higher harmonic feedback of inverter to the grid, so no harmonic wave of power grids, while this equipment for a rectifier output circuit, the power factor is above 95%. The series inverter in the power cabinet adopts frequency modulation and power adjustment, that is, the equipment power is regulated by changing the inverter frequency, the rectifier part of the thyristor is completely in the open state, inductance, and capacitance filtering, unlike parallel resonance to adjust the DC voltage to adjust the output power. In the process of intermediate frequency electric furnace drying and later insulation, the thyristor is still in full operation, which greatly improves the power factor of the equipment and prevents the pollution of high order harmonics to the power grid.

Mainly from higher harmonic adjustable burrs on thyristor voltage rectifier part, would seriously pollute the power grid, lead to other equipment cannot work normally, and energy-saving series resonant frequency power supply way of rectifying part adopts half controlled rectifier, a dc voltage is always working at the highest, not the conduction Angle, so it won’t produce higher harmonics, not pollution grid, not interfere with the factory in other electronic equipment operation.

Product features of Metal Smelting Furnace

● The metal smelting furnace is a large capacity furnace, high rigid structure design, strong and durable.

● Silicon steel magnetic yoke reduces magnetic flux leakage, improves thermal efficiency, and increases output.

● Free from local voltage fluctuations, the equipment can be used 24 hours a day.

● It will not pollute the power grid or interfere with the operation of other electronic equipment in the factory.

● The thyristor is the main control element in the thyristor if the power supply to achieve a better energy-saving effect.

● And the performance is very stable, easy to maintain.

● Low harmonic interference, high overload capacity, and low maintenance cost.

● The inverter trigger system adopts phase-locked tracking control to ensure the inverter system operates under a high power factor

● High-temperature resistance, heavy pressure, not easy deformation, good safety.

● The furnace body is equipped with an anti-drop protection device to ensure safe production.

Product parameters of Metal Smelting Furnace

Steel melting (1450℃) | |||||||||||||

Capacity(t) | 0.5 | 1 | 1.5 | 2 | 3 | 4 | 5 | 7 | 10 | 12 | 15 | 20 | 30 |

Power(kW) | 400 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 | 6000 | 8000 | 15000 | 20000 |

Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

Melting rate(t/h) | 0.6 | 1.08 | 1.4 | 1.89 | 2.94 | 3.78 | 4.62 | 5.67 | 9.76 | 11.76 | 16 | 30 | 40 |

Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 510 | 500 | 500 | 490 | 490 | 500 | 500 | 500 |

Cooling water flow(m³/h) | 5 | 7 | 10 | 13 | 18 | 25 | 30 | 34 | 55 | 62 | 72 | 92 | 100 |

Aluminum melting(700℃) | |||||||||||||

Capacity(t) | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2 | 3 | 5 | |||||

Power(kW) | 200 | 300 | 400 | 600 | 800 | 1000 | 1500 | 2500 | |||||

Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |||||

Melting rate(t/h) | 0.38 | 0.63 | 0.74 | 1.10 | 1.57 | 1.94 | 2.94 | 4.83 | |||||

Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 500 | 500 | 500 | |||||

Cooling water flow(m³/h) | 5 | 8 | 9 | 12 | 15 | 20 | 26 | 45 | |||||

Copper melting(1250℃)). | |||||||||||||

Capacity(t) | 0.5 | 1 | 2 | 3 | 5 | 7 | 10 | 20 | |||||

Power(kW) | 300 | 500 | 100 | 1500 | 2500 | 3000 | 5000 | 7000 | |||||

Frequency(Hz) | 500 | 500 | 500 | 500 | 250 | 250 | 250 | 250 | |||||

Melting rate(t/h) | 0.53 | 1.16 | 2.31 | 3.57 | 5.75 | 6.86 | 12.7 | 18.5 | |||||

Melting consumption(kwh/t) | 425 | 420 | 410 | 400 | 390 | 390 | 380 | 378 | |||||

Cooling water flow(m³/h) | 9 | 12 | 20 | 28 | 48 | 60 | 85 | 100 | |||||

Our services

● Manufacturer direct sale, after-sale has safeguard.

● 7*24h Free technical consultation.

● Free training for use.

● Free installation instructions.

● All equipment will be closely tested before leaving the factory.

● We will provide environment-friendly export packing that meets the requirements.

● Prompt delivery, 12 months complete machine warranty.

● Beyond the warranty period, we provide lifelong free technical service and cost accessories service for the equipment.

Application of Metal Smelting Furnace

This metal smelting furnace adopts series resonant medium frequency power supply, its inverter device is the half-bridge series inverter, it is mainly used for melting ordinary carbon steel, alloy steel, cast steel, non-ferrous metal, aluminum alloy. Widely used in metallurgy, forging, casting, refining, machinery, building materials, automotive manufacturing, and other industries.

FAQ of Metal Smelting Furnace

● Are you factory direct?

Yes, we are.

● What kind of packing?

Each of our export equipment has professional export packaging, to meet the environmental requirements.

● Does the quotation include freight?

The quotation is the arrival price for export to domestic ports. Ports are generally: Qingdao, Shanghai, Shenzhen. Customers can also specify any domestic port or airport. If there are special requirements, we can also quote the price including express or air freight to the customer’s location.

● How can I get your installation service?

For simple general-purpose equipment, we will provide illustrated installation instructions and installation videos, as well as detailed maintenance instructions. For complex products, if they cannot be installed through the information provided by us, we will arrange for a skilled engineer to provide door-to-door guidance. Our products have been exported to many countries around the world. we have a wealth of solutions. You don’t have to worry about that.