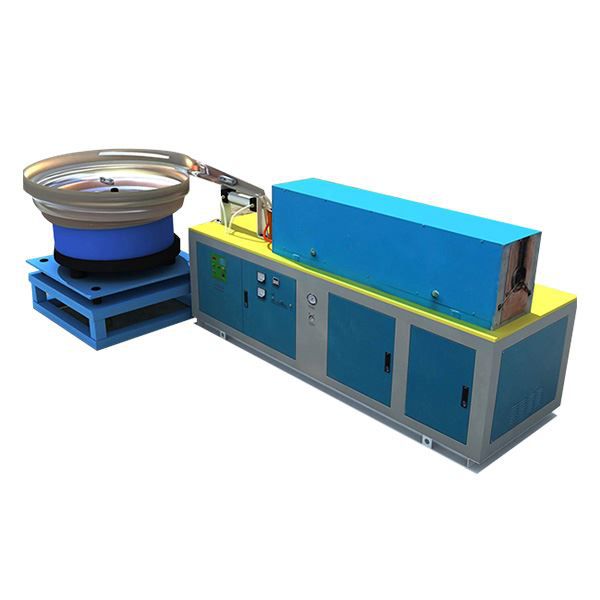

Structure of Medium Frequency Forging Furnace

20 years in the induction forging field, our medium frequency forging furnace matches with the manipulator, infrared temperature measuring device, billet material loader, and unloader can finish different shape billet heating forging projects.

Technical sheet of Medium Frequency Forging Furnace

Medium frequency forging furnace is mainly used for above diameter 12mm steel, stainless steel, copper, and aluminum material round bar, square bar, and another shape blank material, etc continuous heating forging. Not only can used for whole billet heating forging but also can use for partial forging, like billet end forging, billet middle part forging, and so on.

Forging model | Heat steel or stainless steel to 1050℃ | Heat copper to 700℃ |

KQZ-35 | 1.25KG/Minute | 1.75KG/Minute |

KQZ-45 | 1.67KG/Minute | 2.33KG/Minute |

KQZ-70 | 2.5KG/Minute | 3.5KG/Minute |

KQZ-90 | 3.33KG/Minute | 4.67KG/Minute |

KQZ-110 | 4.17KG/Minute | 5.83KG/Minute |

KQZ-160 | 5.83KG/Minute | —— |

KQZ-240 | 8.6KG/Minute | —— |

KQZ-300 | 11.25KG/Minute | —— |

KQZ-500 | 17.9KG/Minute | ——– |

Features of Medium Frequency Forging Furnace:

◆ Wide frequency range, 100Hz-20KHZ, as per the heated parts to choose the suitable frequency range.

◆ When doing the whole billet bar forging, the medium frequency induction heating coil length is 500mm-1m, heat several pieces of the bar at the same time to ensure the forging result.

◆ Medium frequency induction forging furnace adopts the continuous heating method, the induction coil inside load is uniform, during the heating process, Single bar feed load rises from room temperature to 1100 degrees, the huge load changes cause the machine actual heating power changes, to makes the actual power of the equipment be guaranteed to be above 85% of the rated power in the whole continuous heating process, so that the equipment can be effectively used

◆ When heating non-ferrous metals such as copper and aluminum, the actual power of the equipment can also be utilized to more than 85% of the maximum power through the reasonable coil and capacitor design, and the heating capacity of the equipment can reach 3.5KG/ KW.h when heating copper.

◆ Compared with SCR if power supply, is not only small in size, easy to maintain but also can save 15%-20% of the power.

Our service and mission

We have been working in the induction heating industry for more than 20 years. We insist on doing every piece of equipment well with our heart and strengthen our team with love.No matter how the years change, we are always exploring the way of innovation, and strive to use advanced, the most economical heat treatment scheme, to serve each of our users. Adhere to do induction heating green supply chain, so that each of our users can be worry-free to enjoy our every service and sincere.

No matter where you are, No material at what time, When you need us, We are online 24 hours for your calling.