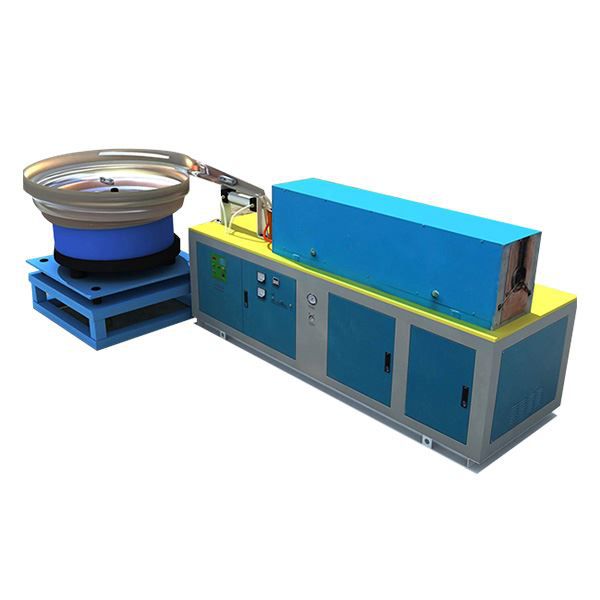

Performance characteristics of Induction Forging Equipment

● The central control circuit board is optimized by computer, the induction forging equipment unit circuit is optimized, and combined, the device has stable performance, reliable quality, and strong anti-interference.

● Components layout coordination and reasonable, easy maintenance.

● On the basis of zero voltage starting, automatic frequency sweep and repeat starting function is added, the voltage and current loop circuit are closely tracked, the device starts and stops smoothly and stably, without current shock.

● The inverter starting signal adopts a single signal high sensitive trigger circuit, which further increases the equipment starting performance and makes equipment the starting success rate reaches 100%.

● Constant power circuit control system can adjust the voltage and current automatically at the optimal setting with the change of charge in the production without manual adjustment of the inverter cut-off Angle.

● With perfect over-voltage, over current, under voltage, water shortage, phase shortage, voltage, and current limit protection system, so as to ensure the equipment using reliability and stability.

● Highly integrated circuit scheme, debugging and operation is fast, simple, and easy to learn.

Technical data of Induction Forging Equipment

Rated power | Rated frequency | Transformer | Induction | Power consumption | Billet diameter | |

Volume(KVA) | secondary voltage(V) | |||||

10000 | 70-1500 | 12500 | 950 | 2800 | 300 | 2500-1500 |

8000 | 80-1500 | 1000 | 950 | 2800 | 320 | 1500-1200 |

5000 | 80-1500 | 6000 | 950 | 2800 | 340 | 1000-1200 |

3000 | 400-1500 | 3500 | 850 | 2800 | 350 | 800-1000 |

2000 | 500-1000 | 2200 | 850 | 1200 | 360 | 400-800 |

1500 | 500-1000 | 1600 | 660-380 | 1200 | 370 | 250-400 |

1000 | 500-1000 | 1250 | 660-380 | 1200 | 380 | 150-250 |

500 | 500-8000 | 630 | 660-380 | 800 | 450 | 120-150 |

400 | 500-8000 | 500 | 3*380 | 800 | 450 | 80-120 |

350 | 1000-8000 | 500 | 3*380 | 800 | 450 | 80-120 |

250 | 1000-8000 | 400 | 3*380 | 800 | 450 | 60-80 |

200 | 1000-8000 | 315 | 3*380 | 800 | 450 | 40-60 |

160 | 1000-8000 | 250 | 3*380 | 800 | 450 | 40-60 |

120 | 1000-8000 | 200 | 3*380 | 800 | 450 | 30-50 |

100 | 1000-8000 | 160 | 3*380 | 800 | 450 | 25-40 |

80 | 1000-8000 | 100 | 3*380 | 800 | 450 | 6-35 |

Memo: The above induction forging equipment technical data is just for reference only, the technical proposal is as per the real forging material details. | ||||||

Maintenance and service of Induction Forging Equipment

● Correct maintenance can ensure the equipment has good working performance and long service life.

● Requirements for water cooling: Water cooling is extremely important for induction heating equipment. Poor water quality will lead to rust and scaling inside the equipment and blockage of pipelines, which will directly lead to equipment damage and failure to work normally.

● Recommended cooling water: distilled water — softened water — purified water — filtered tap water.