- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

Enquire

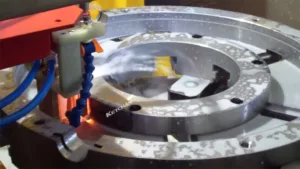

Surface heat treatment of steel parts

Operation method:

Put the steel piece into the inductor to make the surface of the steel piece generate induction current, heat it to the quenching temperature in a very short time, and then spray water to cool it.

Purpose:

Improve the surface hardness, wear resistance, and fatigue strength of steel parts, and maintain the toughness of the core.

Application points:

- Mostly used for medium carbon steel and medium carbon alloy structural steel parts;

- Due to the skin effect, the depth of the UHF induction hardening layer is generally 0.1~1mm. The hardening layer depth of high-frequency high-frequency induction hardening is generally 1-2mm, that of medium-frequency hardening is generally 3-5mm, and that of high-frequency hardening is generally greater than 10mm. The quench hardened layer is affected by the frequency of the induction heating power supply, the heating time and the temperature of the coolant.

Share this article to your platform: