- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

Enquire

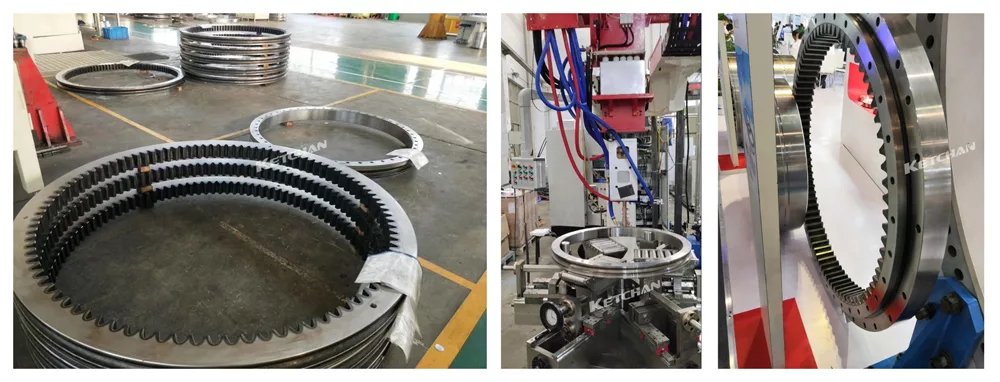

Induction Hardening of Cantilever Gear

Cantilever gear CNC induction quenching machine has manual operation and automatic operation functions, suitable for single and batch parts production, with continuous quenching, simultaneous quenching, and other processes, mainly used for large rotary bearing, inner teeth, outer teeth, tooth surface, and other ring parts of the overall quenching, at the same time can be used for wheel, ring and plane parts of the induction hardening and widely used in wind power, automobile, construction machinery, machine tool industry induction heat treatment field. Reasonable structure, complete functions, convenient installation, and debugging.

- The structure of the machine adopts the cantilever + rotary table, the beam bears the power load, can be moved up and down, left and right, and the workpiece tooth surface quenching.

- The workpiece is laid flat. Through the 840DSL system, the inductor is aligned with the quenching surface by the load slide and the mobile CNC system to realize the overall quenching of the workpiece.

- Using the Siemens system can achieve accurate clearance control, accuracy deviation ≤0.2mm. The whole equipment includes a set of beam and cantilever, a set of heating load, a set of integrated induction quenching spray sensor.

- Set manual operation interface, flexible wire connection, can be extended to 1 meter away from the load, with power addition and reduction, spray cutting, access, heating cutting, access, displacement hand wheel, and other operations, easy to adjust the product model. After adjustment, the system will automatically record, and the subsequent mass production will not be adjusted.

Share this article to your platform: