Technological advantages of High Frequency Induction Heater

◆ High heating speed: the highest heating speed is less than 1 second.

◆ Wide application fields: can heat all kinds of different metal workpieces.

◆ Easy to install: connect the induction heaters power supply, induction heating coil, and the inlet&outlet water pipes are ok. Small volume and lightweight.

◆ Easer operation: workers can use it in several minutes.

◆ Fast starting time: The heating can be started after turn on the water and power.

◆ Energy-saving: It saves 70% more power than the old vacuum tube high-frequency induction heaters.

◆ Good heating efficiency: the heating result is uniform, fast-rising temperature, the oxide layer is small, no waste parts after annealing.

◆ Perfect self –protection functions have over-voltage, over-current, lack of water alarm indicators, and also have the automatic control and protection.

◆ Controlled temperature: through the set heating time to control the workpiece heating temperature.

◆ Full load design: 100% full load design, can work 24 hours continuously.

◆ Small volume: lightweight, green environment.

◆ No high voltage: safety voltage, can customize 380V-480V voltage.

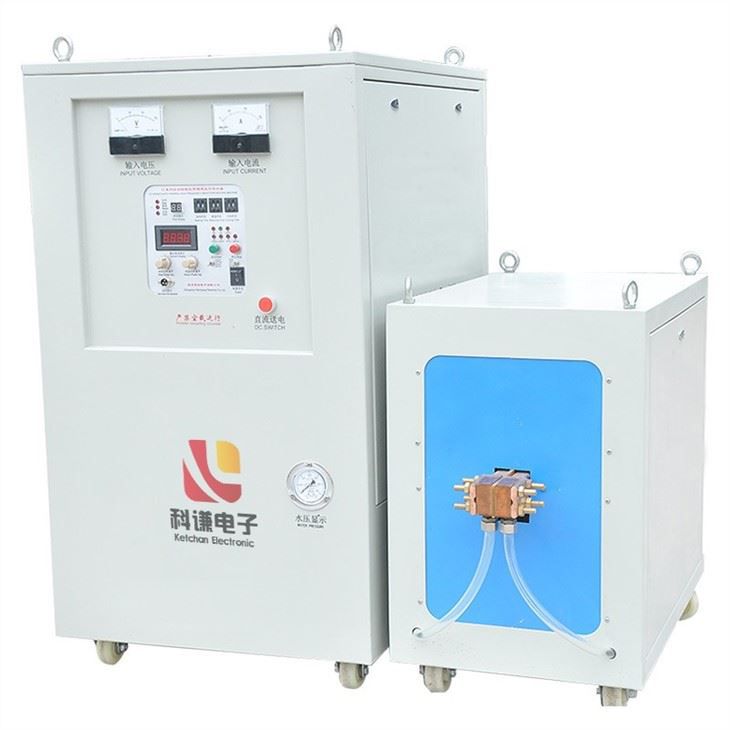

Technical Parameters of High Frequency Induction Heater

Model | Max input power | Frequency |

KQG-15 | 15KW | 30-100KHZ |

KQG-25 | 25KW | |

KQG-35 | 35KW | |

KQG-45 | 45KW | |

KQG-70 | 70KW | 30-80KHZ |

KQG-100 | 100KW | |

KQG-120 | 120KW | |

KQG-160 | 160KW | |

KQG-200 | 200KW | |

KQG-250 | 250KW | |

KQG-300 | 300KW |

Application cases of High Frequency Induction Heater

Our high-frequency induction heaters are mainly used for the following metal heating fields.

◆ Mainly used for the shaft, gear hardening, inner hole hardening, hardening depth can reach less than 2mm.

◆ Carbon steel screws and stainless steel screws heated glue.

◆ Saw blades continuous quenching, stainless steel, and alloy steel filaments annealing or quenching.

◆ Carbide saw-tooth welding, reamer welding, communication cable joint welding, filter capacitor welding.

◆ Weld metal pipe joints, continuously welding.

Our Service

◆ Be clear about customer workpiece requests and make suitable heat treatment solutions.

◆ Face to face quotation and solve the customer’s heating process trouble.

◆ Free process testing, and choose a suitable model.

◆ Perfect after-sales service, professional technical training.