- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

- UHF Induction Heating Machine

- HF Induction Heating Machine

- MF Induction Heating Machine

- Induction Heat Treatment Machine

- Air Cooled Induction Heater

- CNC Hardening Machine Tool

- Induction Brazing Systems

- Portable Induction Heater

- Induction Forging Machine

- Metal Melting Furnace

- Induction Coils

- Resistance Furnace

- Infrared Thermometer

- Industrial Cooling Machine

- Induction Heating Transformers

- Custom Induction Heating Systems

Enquire

Application of induction heating in the wind power industry

ZHENGZHOU KETCHAN ELECTRONIC CO.,LTD is China’s leading supplier of heating solutions in the renewable energy field. Our technology has already made a huge contribution to the efficiency, safety, and profitability of the wind turbine industry – making the manufacture and maintenance of turbines a clean and green process.

Clean and green process:

Induction heating is essentially a cleaning process. It is more energy efficient and environmentally friendly than other heating alternatives. It emits no carbon dioxide. It eliminates open flames, reduces the need for fuel transportation, and promotes safer and healthier workplaces. Product quality and process consistency are critical to the wind turbine industry, which is why accurate, repeatable, and contact-free induction heating has become the standard for wind turbine manufacturers and their suppliers. Wind turbines are exposed to harsh weather conditions, so they must be able to withstand strong winds, especially in harsh offshore environments. Rotor bearings and large gears must be custom hardened to withstand heavy loads and punishing torques, and some high quality mission-critical components require hot fitting, brazing, and preheating.

Almost every part of a typical modern wind turbine uses induction heating.

Cable induction heating

Preheat the base plate before welding

Base bolt heating

Brazing components in high-voltage boost transformers

Brazing of high voltage cable terminals

Preheat the tower ring before welding

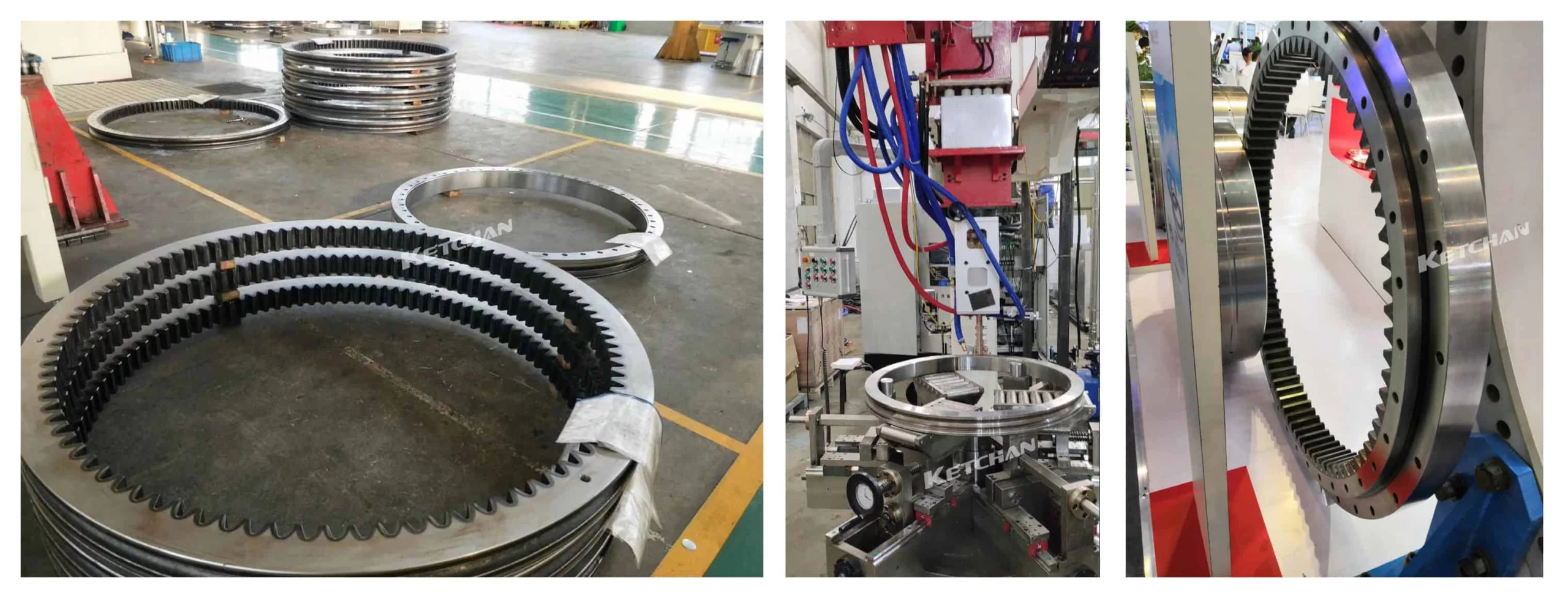

Hardening of variable paddle bearings

The stator housing of the yaw motor and variable rotor motor is hot installed

Hardening of bearings and slewing supports

Shrinkage fit of spindle bearing and bushing ring

Hardening of gearbox shafts and bearings

Hardening of generator bearings

Brazing of stator and rotor windings

Brazing components in high voltage boost transformers

Hardening of gears for yaw drive and slewing support

Cable induction heating

Preheat the base plate before welding

Base bolt heating

Brazing components in high-voltage boost transformers

Hardening of gears for yaw drive and slewing support

Shrinkage fit of spindle bearing and bushing ring

Share this article to your platform: